Quartz crystal is an electronic component that utilizes the piezoelectric effect of quartz to generate high-precision oscillation frequencies. Quartz has become an important component which is widely used in various electronic devices due to its physical characteristics of low temperature coefficient and high Q value. Taitien is one of the few manufacturers who owns its in-house wafer cutting technology. By vertically integrating the production of upstream quartz wafers, wafers’ angles and thicknesses are cut precisely so as to control the material source and quality. Taitien is keenly aware of the mainstream development of electronic products that are light and thin, as well as the demand for high-speed transmission and high-frequency communication. We provide a variety of miniature, low-power consumption, high-precision and wide-temperature quartz crystals to satisfy customers’ diversified needs for quartz components.

▌The TAITIEN Advantage

- Industry 4.0 is introduced to build the Internet of Machines and realize smart manufacturing to satisfy customers’ needs

- Quartz crystal and oscillation circuit loop analysis are provided to enable customers to find the most stable matching combination

- Readily available with better delivery time which quickly support samples and follow-up mass production services

▌Applications

5G mobile phone (smart phone), smart meter, smart home, IoT, Wi-Fi 6/6E, Bluetooth, Low-Power Wide Area Network (LPWAN), desktop/ notebook/ gaming computers, smart cockpit, in-vehicle communication, long and short-range radar, car infotainment and edge computing products

»» kHz Quartz Crystal Series (kHz XTAL)

|

||||

|

|

|

|

|

|

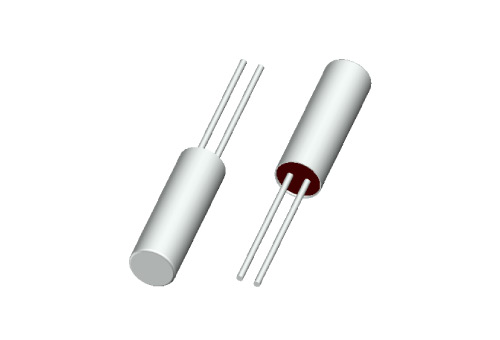

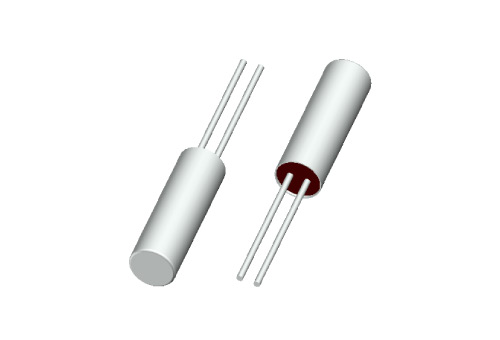

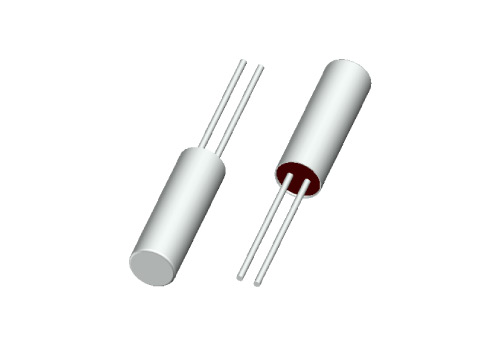

Ø1 x 4.6 mm

32.768 kHz

±20 ppm @

-40°C to +85°C

|

Ø2 x 6 mm

32.768 kHz

±20 ppm @

-40°C to +85°C

|

Ø3 x 8 mm

32.768 kHz

±20 ppm @

-40°C to +85°C

|

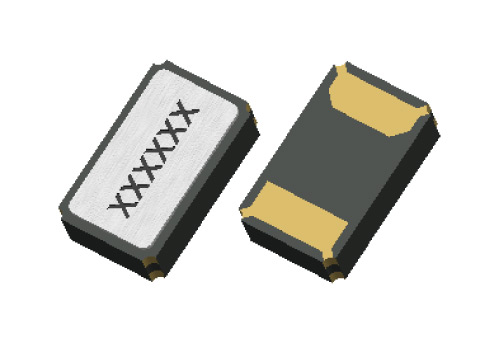

2 x 1.2 mm

32.768 kHz

±20 ppm @

-40°C to +85°C

|

3.2 x 1.5 mm

32.768 kHz

±20 ppm @

-40°C to +125°C

AEC-Q200

|

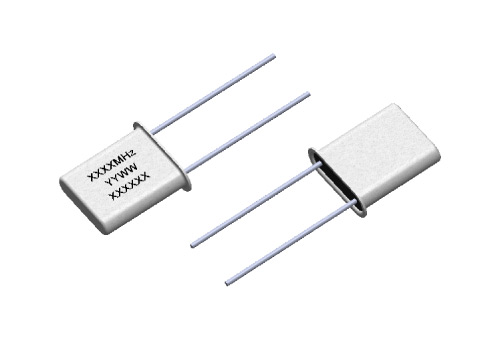

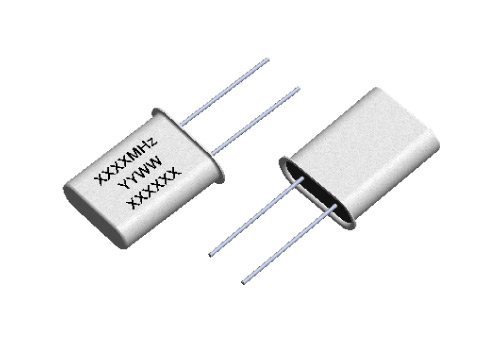

»» MHz Quartz Crystal Series (MHz XTAL)

|

||||

|

|

|

|

|

|

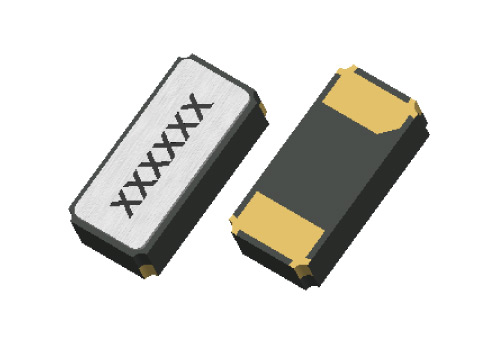

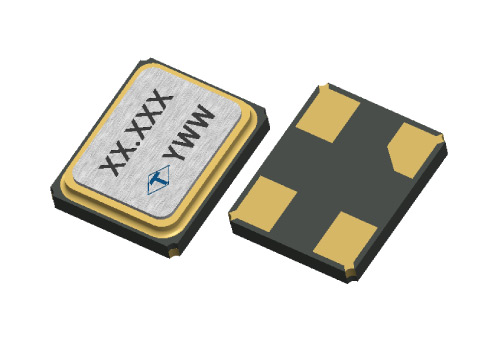

1.65 x 1.25 mm

24 to 54 MHz

±5 ppm @

-10°C to +60°C

|

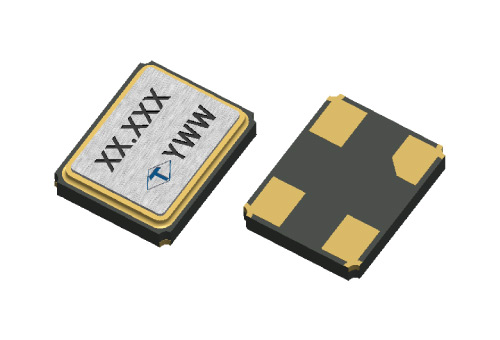

2.05 x 1.65 mm

16 to 60 MHz

±30 ppm @

-40°C to +125°C

AEC-Q200

|

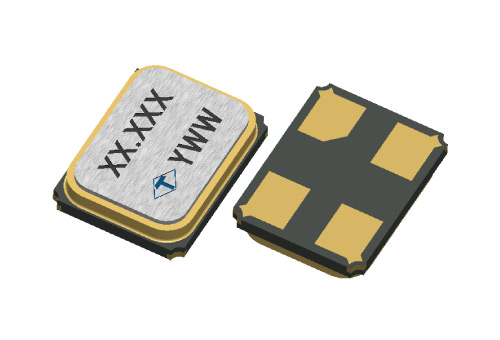

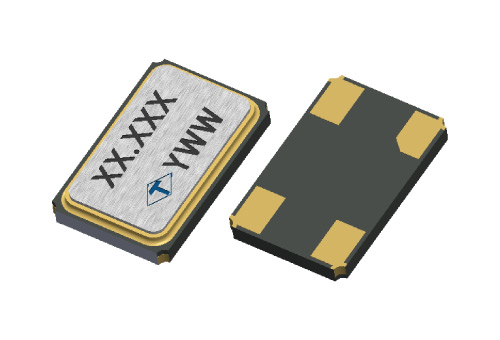

2.5 x 2 mm

12 to 54 MHz

±30 ppm @

-40°C to +125°C

|

3.2 x 2.5 mm

12 to 60 MHz

±30 ppm @

-40°C to +125°C

AEC-Q200

|

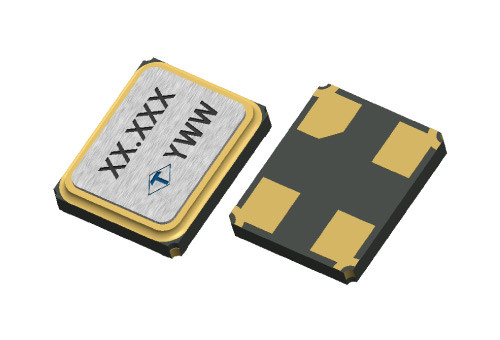

5 x 3.2 mm

8 to 80 MHz

±30 ppm @

-40°C to +125°C

AEC-Q200

|

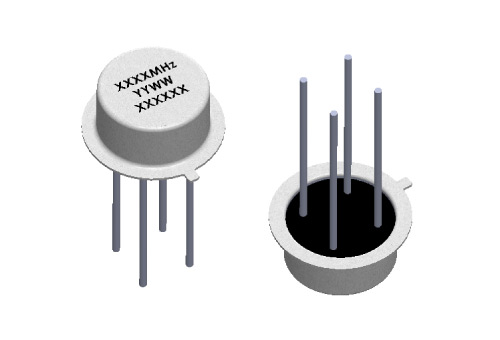

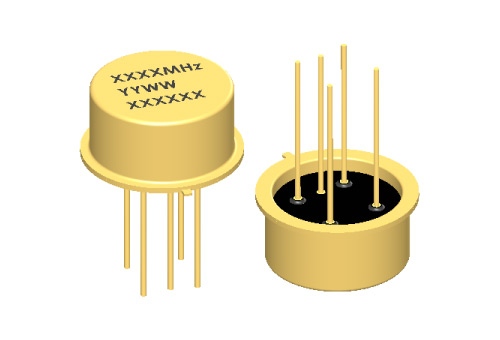

»» High Precision Quartz Crystal Series (High Precision XTAL)

|

||||

|

|

|

|

|

|

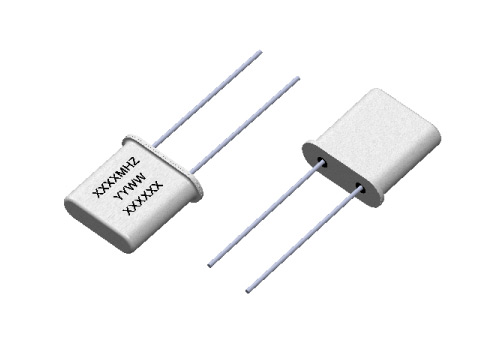

7.9 x 3 x 7.8 mm

8 to 100 MHz

±10 ppm @

+75°C to +105°C

|

8.6 x 3.1 x 8 mm

19.2 to 128 MHz

±10 ppm @

+75°C to +105°C

|

11.2 x 4.8 x 13.47 mm

4 to 128 MHz

±5 ppm @

+75°C to +105°C

|

Ø10.2 x 5.6 mm

19.2 to 120 MHz

±8 ppm @

+75°C to +105°C

|

Ø15.2 x 5.2 mm

4 to 100 MHz

±5 ppm @

+75°C to +105°C

|