High Precision SC Cut Crystal

Crystal

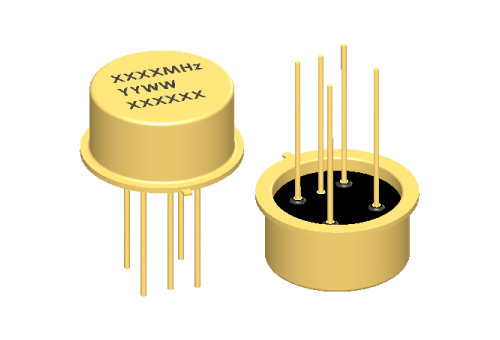

Taitien’s high-precision SC quartz crystal resonators leveraged the high-Q SC-cut wafer design technology. These devices deliver superior performances such as transient thermal compensation, stress compensation, low sensitivity to drive level (can withstand high drive level) and has higher capacitance ratio C0/C1 (the △ƒ caused by the change of oscillator reactance is relatively small), so it is widely used in ranging, high-speed target tracking, low noise crystal oscillators in outer space communication systems, tactical crystal oscillators that require quick start and crystal oscillators used under environments with strong radiation, strong vibration and drastic temperature changes. Taitien also provides a variety of package sizes and structures.

- Excellent power-on characteristics: Since the thermal overshoot of a SC-cut resonator is about 2 orders of magnitude smaller than an AT-cut, the SC-cut crystal oscillator can quickly reach its frequency stability after powering up. In general, the stability can reach 2×10-9 after powering up for 6 minutes.

- Low aging: The stress effect of the SC-cut resonator is small and the aging caused by stress relaxation is also small. The aging rate can reach 10-11/d.

- Outstanding short-term frequency stability: After the drive level is increased, the signal-to-noise ratio relative to the white noise is increased, thus the far-end phase noise can be improved. Currently, the highest level can reach -160~-170 dBc/hz and the near-end phase noise at 10 Hz frequency offset can reach -130~-140 dBc/Hz.

- Applications: Oscillators used for measurement equipment, computers, home appliances, communications and other fields